Proof Pressure vs. Burst Pressure in Heavy-Duty Pressure Gauges

Key Takeaways

- Proof pressure is the highest pressure a gauge can experience without drifting out of calibration.

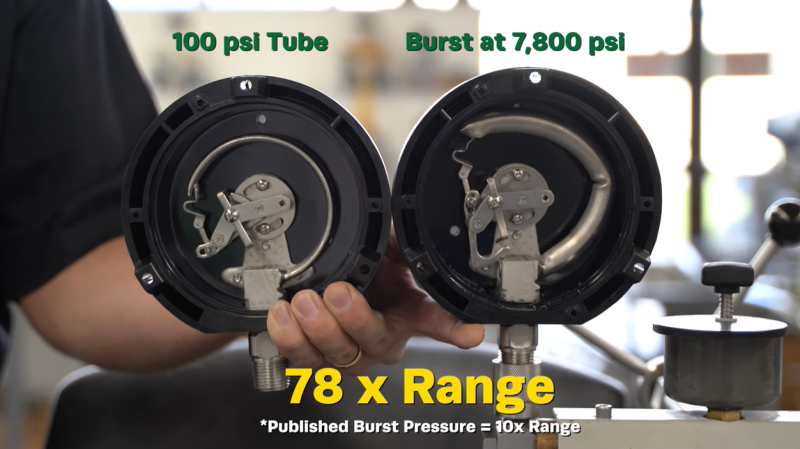

- Burst (rupture) pressure is the catastrophic limit at which the bourdon tube will leak or fail.

- Reotemp heavy-duty gauges are proof-tested to 130 % of range (110 % above 5 000 PSI) and burst-tested to 1.5 to 10 × the rated range, depending on scale.

- ASME B40.100 recommends steady operation between 25 to 75 % of span

Why Engineers Ask About “Proof Pressure” and “Burst Pressure”

Every instrumentation engineer has opened a spec sheet and wondered, “Will this gauge survive the start-up surge?”

Process upsets, compressor kicks, and valve slams can momentarily spike line pressure well above the normal set-point. If the spike exceeds the gauge’s proof pressure, the bourdon tube yields and the pointer never returns to zero, throwing off every subsequent reading. Surpassing burst pressure can rupture the tube, releasing process fluid and endangering personnel.

Understanding these two limits, and how they appear in standards such as ASME B40.100, lets you size gauges confidently and avoid unplanned downtime.

What Do the Terms Mean?

Proof Pressure (Over-Pressure)

ASME B40.100 definition: the maximum pressure a gauge can withstand without plastic deformation of the pressure element. Think of proof pressure as the elastic limit of the tube; short excursions up to this level may occur, but the gauge will spring back to it’s original calibration band.

Burst (Rupture) Pressure

This is the maximum pressure the bourdon tube can hold before developing a leak. The burst pressure rating includes a built-in safety factor, well above proof pressure, to guard against catastrophic failure. It is not a rating for routine operation.

How Reotemp Rates Its Heavy-Duty Gauges

| Gauge Range | Reotemp Proof Pressure | Reotemp Burst Pressure* | Safety Factor vs. Proof |

|---|---|---|---|

| 15 to 200 PSI | 130 % of span | 10 × span | 7.7 × |

| 300 to 1,000 PSI | 130 % of span | 5 × span | 3.8 × |

| 1,500 to 4,000 PSI | 130 % of span | 2.5 × span | 1.9 × |

| ≥ 5,000 PSI | 110 % of span | 1.5 × span | 1.36 × |

*Derived from sample burst tests on completed bourdon-tube/socket assemblies.

Tip: For pulsating processes, consider a gauge one range higher than normal so that steady-state readings fall within the recommended operation pressures.

Operating Guidelines for Long Gauge Life

1. Size the Range for Normal Running, Not the Spike

- Keep continuous operating pressure between 25 to 75 % of full scale.

- Ensure that intermittent peaks never exceed the proof-pressure rating.

2. Dampen Pulsation

Prevent oscillations or sudden pressure spikes from hammering the bourdon tube. Install pressure snubbers or over-pressure protectors (limiting valves) upstream of the instrument.

3. Verify the Transient

Where possible, log the pressure profile during start-up to quantify spike amplitude and duration. This data helps determine if a gauge with a higher proof pressure rating is needed to ensure reliable operation and avoid damage from pressure spikes.

Gauge Proof Pressure and Diaphragm Seals

When considering attaching a diaphragm seal to a gauge, you must look one additional limit:

- Maximum Working Pressure (MWP): This is the highest continuous pressure the diaphragm seal is designed to operate at while maintaining accuracy.

Note: Note: Proper gauge and diaphragm seal selection requires evaluating MWP, proof pressure, and burst pressure to ensure safe and reliable operation.

Frequently Asked Questions

Why is proof pressure expressed as a percentage while burst is a multiple?

Proof pressure relates to the elastic limit of the bourdon tube, which is proportional to material yield strength—hence a percentage of span. Burst pressure reflects ultimate tensile failure, so a multiplier better conveys the safety margin.

Can I continuously operate at 90 % of scale if the spikes stay below proof pressure?

No. ASME B40.100 limits continuous loading to ≤ 75 % of full scale to prevent fatigue and mid-scale pointer error, even if spikes are proof-safe.

What happens if I exceed proof pressure once?

The gauge may appear fine, but hidden plastic deformation can offset calibration. Always compare the reading to a reference after a suspected over-pressure event.

How do snubbers work?

They reduce the impact of pressure spikes by slowing the rate at which pressure reaches the gauge. They use restrictive elements such as porous metal discs and small-bore pistons to dampen sudden pressure changes. This helps prevent the bourdon tube from exceeding proof pressure temporarily.

Does ambient temperature affect proof pressure?

Yes. Elevated temperatures reduce material yield strength, so apply derating factors or choose a gauge certified for high-temperature service.

Conclusion

Proof pressure ratings protect accuracy, while burst pressure ratings protect people. By staying in the recommended operating pressure range of 25 to 75% of full scale, installing surge damping, and checking diaphragm seal maximum working pressures limits, you can ensure that a simple mechanical gauge remains the most reliable, lowest-cost sensor in your plant.

Need a rugged gauge fast? Check out our Reotemp Texas Edition Process Gauge or Repairable, Heavy-Duty Stainless Gauges , or contact our applications team for help specifying the right proof-pressure class.