Steel Industry Instrumentation

Reotemp is an American manufacturer specializing in pressure and temperature instrumentation for the Steel Mill Industry. Our instruments are designed to deliver dependable measurements and perform exceptionally well in challenging, high temperature environments.

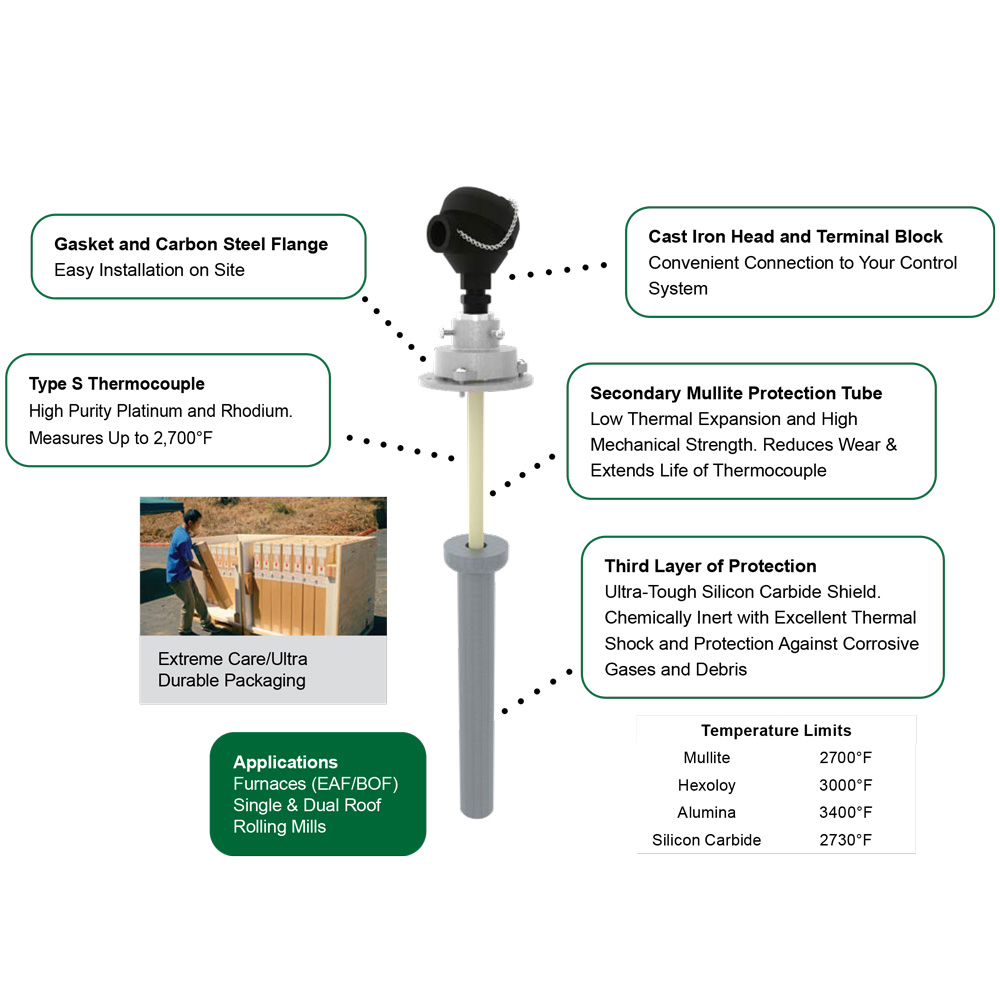

High Temperature Thermocouples

Designed to Maximize Thermocouple Lifespan

For nearly six decades, Reotemp Instruments has been at the forefront of precision temperature measurement. Our commitment to excellence, coupled with our ‘Made in the USA’ pride, has established us as a trusted partner for steel manufacturers. In the unforgiving world of steel production, where extreme temperatures and harsh conditions are the norm, Reotemp’s thermocouples have consistently risen to the challenge, providing the accuracy, reliability, and durability that the industry demands.

Thermocouples and RTDs

Stem Assembly with Plug Connection

Allows for quick connection and disconnection. Standard plugs (round pins) and mini plugs (flat pins) are available.

Stem Assembly with Plain Leads

Typically used to hook up to a transmitter or terminal block close to the location of the stem.

Head Assembly

Cut-to-Length Temperature Probes

Designed as a fast and temporary replacements for applications where downtime needs to be minimized. Supplied in standardized lengths and can be cut down as needed in the field.