How to Select A Pressure Gauge

All pressure gauge components should be selected after consideration of the pressure, temperature, media characteristics, and environmental factors. Misapplication or improper installation can cause gauge failure, which can result in damage to other equipment or personal injury. We suggest that users of pressure gauges become familiar with ASME B40.100 which is available at www.asme.org.

To ensure safety, accuracy, and gauge life, good practice requires the consideration of the following factors when selecting a pressure gauge:

1. Pressure Range

Reotemp gauges can measure pressures from full vacuum to 30,000 psi and gauge and differential pressures as low at 10 inches of water column. Generally, a range of twice the working pressure is recommended with a maximum working pressure not to exceed 75% of scale. If pulsation occurs or media temperature is elevated, then working pressure should be at or below 50% of scale.

Most Bourdon tube and capsule gauges can see momentary spikes of 130% of scale without permanent damage to the gauge (see data sheets for specific max working pressure). Information on gauge burst pressure is available on our tech brief page and in the videos below.

Pressure Gauge Burst Pressure vs. Proof Pressure

The Max Working Pressure (or Proof Pressure) of a pressure gauge is often misunderstood as the burst (or rupture) pressure. In this video we show the differences between the two and demonstrate how the bourdon tube reacts to pressures well above its measuring range.

Pressure Gauge Safety – Over Pressure Protection

Mechanical pressure gauges are susceptible to damage and false readings when over-pressured. Learn how certain pressure gauge features can prevent damage and keep users safe.

2. Process Media

All pressure gauge wetted components should be selected to suit the characteristics of the fluid being measured. Consider the following process media characteristics:

Temperature

Specific temperature limits are stated on the gauge data sheets. For media temperatures beyond the gauge limits a diaphragm seal or cooling element should be considered. For steam service a pigtail siphon should be used.

Corrosion

All wetted materials of the pressure gauge are noted on the data sheet. If the process fluid is not compatible with those materials then another gauge should be selected or a diaphragm seal should be installed.

Clogging

The pressure gauge socket and Bourdon tube have small orifices that will clog in the presence of solids or high viscosity fluids. A diaphragm seal is recommended for these applications.

Pulsation

A mechanical pressure gauge is uniquely susceptible to the damaging effects of pulsation in a process. Most Reotemp pressure gauges have restrictor screws (throttle plugs) installed in order to dampen some pulsation. Snubbers can be used to further dampen some types of pulsation. A diaphragm seal with the PulsePlus™ feature is recommended for severe applications.

3. Environmental Factors

The case style, material, and design of the pressure gauge should be selected to suit the environment of the gauge installation. The environmental factors to consider include:

Vibration

Mechanical pressure gauge components are highly susceptible to vibration. Liquid filling of the case is recommended in most applications where vibration exists. In cases of severe vibration the gauge may need to be remotely mounted using flexible capillary tubing with or without a diaphragm seal.

Ambient Temperatures

Most Reotemp pressure gauges are rated for normal ambient temperatures for outdoor installations in most parts of the globe (-40 to 140°F). If the gauge is liquid filled, care should be taken in selecting the right fill fluid for the ambient conditions.

Moisture and Corrosion

The presence of moisture, wash-down chemicals, salt water, and other environmental factors should be considered when selecting case style and material. In high humidity environments, liquid filling the case will avoid condensation buildup on the inside of the lens.

Case Venting and Gauge Burping

Some gauges are susceptible to reading slightly off zero upon receipt or while installed. Watch the video below to learn what causes this issue and how to vent or “burp” a gauge to correct the issue.

4. Accuracy

Reotemp pressure gauges are available in accuracies ranging from 0.25% (ASME Grade 3-A) to +/- 3/2/3% (ASME Grade B). As a general rule, 1% or better gauges are used in critical process and require more costly components and larger dial sizes. All Reotemp pressure gauges are calibrated to the stated accuracy at the time of manufacture; further certification and logging of point data can be provided on NIST traceable reference equipment.

5. Connection Size and Mounting

Most Reotemp gauges come standard with ¼” or ½” Male NPT process connections. Many other connection types are available including BSP, coned high pressure fittings, SAE, tube stub, VCR, and more.

Common Mounting Methods

|

Bottom mount also known as a stem mount. |

|

Rear mount offered in lower back or center back styles depending on the model. |

|

Wall mount includes a back flange attached to the gauge. Offered with a bottom connection or back connection depending on the model. |

|

Panel mount includes a front flange or u-clamp attached to the gauge. |

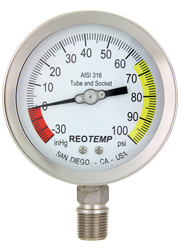

6. Dial Selection

Reotemp pressure gauges are available in dial sizes ranging from 1.5” to 6”. Typically, space consideration, accuracy, and readability are the driving factors behind dial size selection. For pressure gauges being installed into low-light or difficult to read environments, a Hi-Vis™ dial is recommended. Color bands, dual scales, tag numbers, and custom text are other options when selecting a pressure gauge for a specific application.

7. Options

Reotemp Hi-Vis™ Dials

Reotemp’s Hi-Vis dial increases the visibility of dial gauges in low-light environments and at a distance. Hi-Vis dials are often used in areas where gauge readings are paramount to safety of the process. They can also be used to differentiate between two different process lines within a facility.

Color Bands & Color Pies

Color bands and pies highlight a specific range on the gauge so that it is immediately apparent if the process falls within a critical pressure range.

Pressure Gauge Max Pointer – Maximum Pressure Indicator

A mechanical dial pressure gauge is a convenient visual indicator of pressure. By adding a maximum (or minimum) indicator – or tattletale – to the gauge it then becomes an important safety device or troubleshooting guide letting you know what was happening to the gauge while you weren’t watching. Reotemp offers many drag hand options, watch this video to learn more.

Custom Logo Dials

Pressure gauge dials offer a unique opportunity to communicate critical information, highlight installation specifications, or promote an OEM or end-user brand.

Dial Marking

Add text, a serial number, tag number, equipment class, or other text to the gauge dial face.

Pressure Gauge Lens Protector

Do you have dial pressure gauges that operate in areas that collect duck, particulates, paint, fog or other obstructions that prevent you from reading the dial? The Pressure Gauge lens protector might be the right solution for you.