Reotemp is the Top Choice for Diaphragm Seals

Reotemp manufactures a wide range of diaphragm seals in the USA for industrial markets. These diaphragm seals are designed, built, and tested to ensure maximum performance, increased instrument durability, and operator safety. In addition to superior product quality, Reotemp also provides excellent customer service, user-friendly online product configurators, and the fastest lead times in the industry.

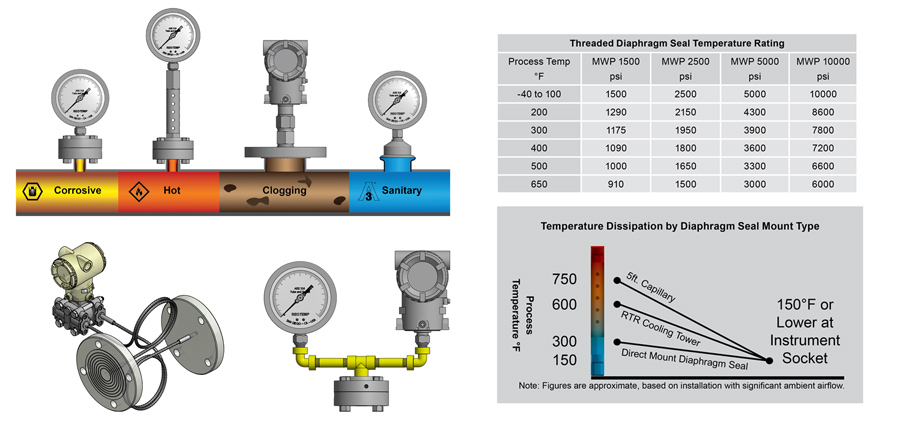

Products

Additional Diaphragm Seal Reference Material

View our diaphragm seal reference material page for more information on frequently asked questions, mounting and fill guides, technical information, and attachment to smart transmitters.