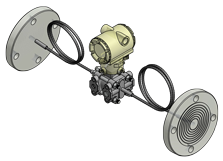

Diaphragm Seal Assembly to Smart Transmitters

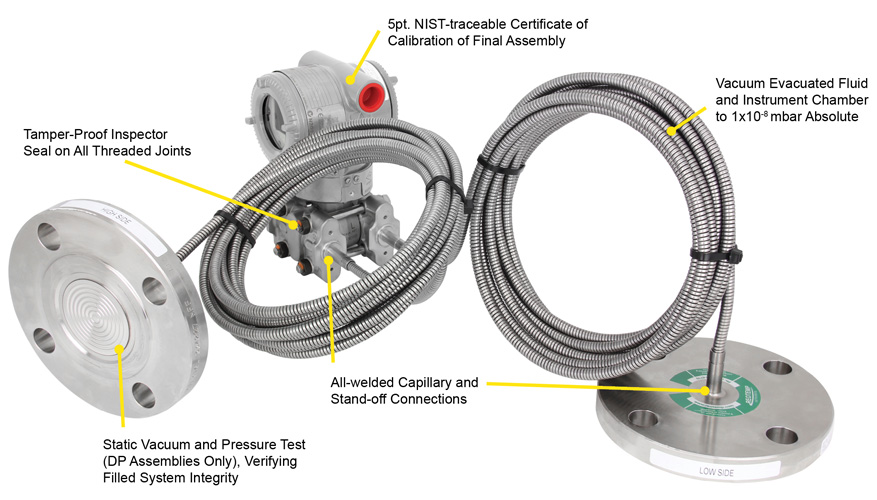

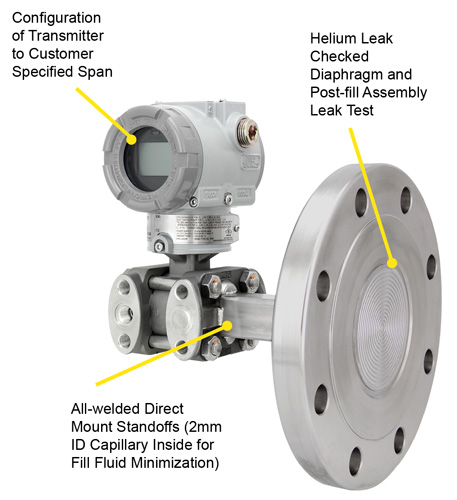

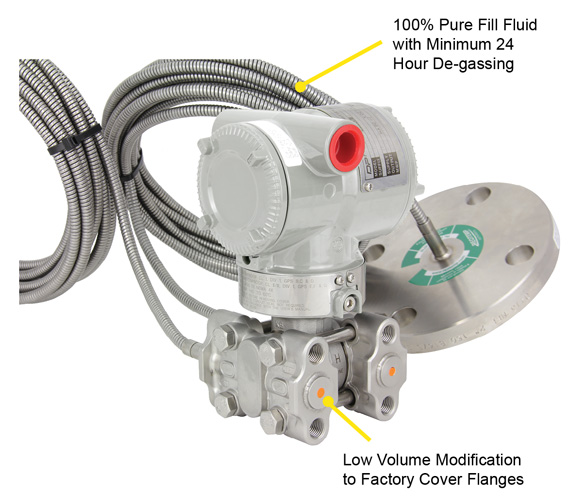

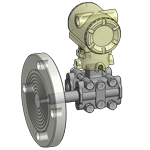

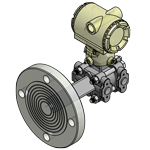

REOTEMP specializes in the unique craft of assembling diaphragm seals to field transmitters for the purpose of measuring pressure, differential pressure, level, and flow. As a trusted supplier to many of the world’s leading transmitter manufacturers, REOTEMP can assemble a diaphragm seal system to virtually any make or model transmitter. Every transmitter mount includes the features below to ensure superior performance and durability for every assembly. REOTEMP also offers repair, refurbishment or replacement of used transmitters with remote seals.

Standard Features on all REOTEMP Assemblies |

|

|---|---|

|

|

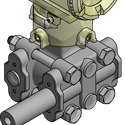

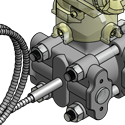

Smart Transmitter Attachment for Differential Pressure Assembly

| Balanced System: A complete assembly with one part number that includes two diaphragm seals, two capillaries, two fills, and one complete assembly calibration certificate. | ||

|

Code: RR | Identical system on HP and LP Sides, capillary exit through process connections. Capillary mounts only. |

|

Code: RA | Identical system on HP and LP sides, capillary exit through face of cover flange. Capillary mounts only. |

| How To Order: Add the appropriate option code to the end of a diaphragm seal part number. Example: W9FFWR31S-B10-AS-RR | ||

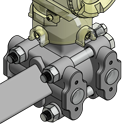

| Unbalanced DP System: Where seal, mount, capillary, or fill is not identical. A complete assembly includes one diaphragm seal on the HP side AND one diaphragm seal on the LP side. | ||

|

Code: RH | (High Pressure Side) Mount via Process Connections |

|

Code: RB | (High Pressure Side) Mount via Face of Cover Flange |

|

Code: RL | (Low Pressure Side) Mount via Process Connections |

|

Code: RC | (Low Pressure Side) Mount via Face of Cover Flange |

| How to Order: Add the appropriate option code to the end of a diaphragm seal part number. An unbalanced system will require two separate part numbers, one for the HP side and one for the LP side. Ex: (High Side Seal) W9FFWR31S-DTD-AS-RB (Low Side Seal) W9FFWR31S-B10-AS-RL | ||

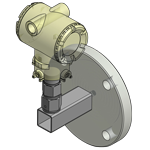

Smart Transmitter Attachment for Gauge Pressure Assembly

| In Line Pressure Transmitter | ||

|

Code: R1 | Mount to In-Line Gauge Pressure Transmitter. Direct or remote mount. |

|

Code: R4 | Horizontal Mount (Tank Mount) to In-Line Gauge Pressure Transmitter. Direct mount only. |

| How To Order: Add the appropriate option code to the end of a diaphragm seal part number. Example: W9FFWR31S-B10-AS-R1 | ||

| Traditional Mount for Gauge Pressure: Seal mount on one side only, other side is vented. | ||

|

Code: R2 | Instrument mount through process connections, HP Side. Use “R3” if mounting to LP side |

|

Code: R8 | Instrument mount through face of cover flange, HP Side. Use “R9” if mounting to LP Side |

| How To Order: Add the appropriate option code to the end of a diaphragm seal part number. Example: W9FFWR31S-B10-AS-R2 | ||