Instrument Mounting Guide

Direct Mount

Direct Mounting a pressure gauge, switch, or transmitter is the most common diaphragm seal assembly.

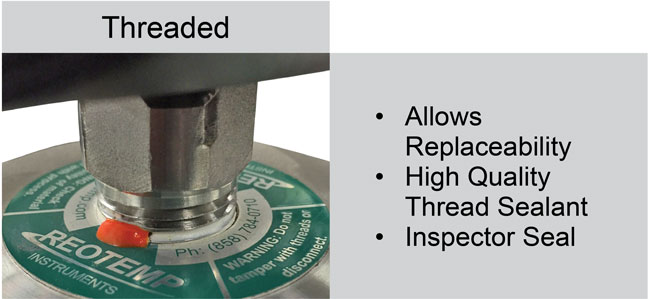

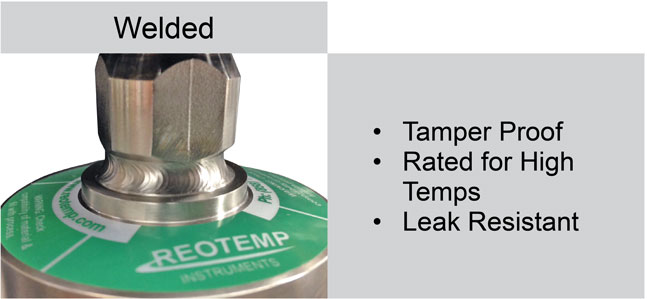

| Code | Description | Max. Temp |

|---|---|---|

| -DTD | Threaded Instrument Connection | 400°F |

| -DWD | Welded Instrument Connection | 600°F |

Assembly Notes: Welded connection recommended for pressure exceeding 1,500 psi for purposes of leak prevention.

Remote Mount

Remote Mounting a pressure instrument using flexible capillary is a common mounting method when the point of measurement is in a hazardous or inconvenient location.

| Code | Description | Max. Temp |

|---|---|---|

| -P?? | PVC Coated SS Armor, Threaded to Seal | 400°F |

| -W?? | PVC Coated SS Armor, Welded to Seal | 600°F |

| -A?? | SS Flexible Armor, Threaded to Seal | 400°F |

| -B?? | SS Flexible Armor, Welded to Seal | 750°F |

| Note: ?? = Length in feet (e.g. 05 = 5 feet) | ||

Assembly Notes: Capillary has a 2mm inner diameter unless specified differently by customer. Ambient temp limit of PVC coated armor is 250ºF. Standard instrument connection is threaded (Smart Transmitters are welded), unless specified by customer.

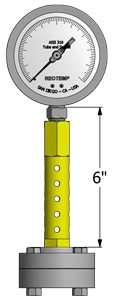

Cooling Elements

Used in either high temp or cold temp applications, Cooling Elements mounted above diaphragm seals quickly normalize fluid temperature toward ambient. This protects the pressure instrument while still maintaining the convenience of a direct mount.

| Code | Description | Max. Temp |

|---|---|---|

| -RTR | 6” Cooling Tower | 750°F |

| -STW | 3” Cooling Standoff | 600°F |

Assembly Notes: Cooling elements are welded to diaphragm seal. Instruments are threaded to cooling element unless specified. All lengths are nominal.

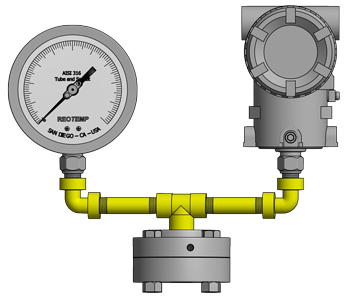

Tree Assemblies

Tree Assemblies offer the ability to mount two pressure instruments onto one diaphram seal, allowing the user to gain both a local indication and a remote signal without adding an additional pipe insertion.

| Code | Description | Max. Temp |

|---|---|---|

| -TRE | Goal Post, Low Pressure Assembly (Max. 150 psi) | 400°F |

| -TRX | Goal Post, Heavy Duty (Max. 3,000 psi) | 600°F |

| -TRM | Compact Tree Assembly (Max. 3,000 psi) | 600°F |

Assembly Notes: Threaded joints are fully welded for consistent instrument orientation. Instrument connections are threaded unless specified by customer. Diaphragm seal must displace enough fluid to drive both instruments.