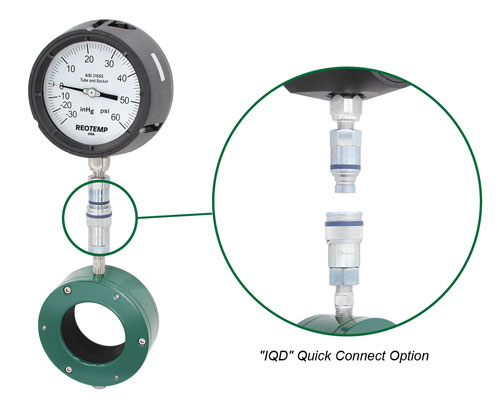

ISOLATION FLOW THRU RING SEAL

The Reotemp ORR Isolation Flow Thru Ring Seal boasts an In-Line Flow-Thru design ideal for waste water, slurries, or abrasives. Mounted between pipe flanges or threaded in-line, it has a tough but sensitive elastomer lining. One unique feature of this seal is the ability to mount multiple instruments on one seal.

Construction Materials

Body: Carbon Steel, 316SS

End Flange: Carbon Steel, 316SS

Diaphragm/Sleeve: Buna-N, Viton, PTFE, EPDM, Natural Rubber and more

Liner/Sleeve Selection

| Sleeve Material | Chemical Resistance and Durability | Limit (°F) |

| Buna-N | Most common in Wastewater market. Limited chemical compatibility. Is an industry standard material that carries a medium/low abrasion resistance. | 225 |

| Viton | Good chemical resistance that can be utilized in many applications. Limited chemical compatibility. Offers the best combination of temperature and high abrasion resistance. | 400 |

| EPDM | Medium level of chemical resistance. Specialized material that performs very well in specific process medias. Offers medium abrasion resistance. | 300 |

| Natural Rubber | Often used in mining applications due to excellent wear properties, however, contains poor resistance to a variety of chemicals. Specialized material that performs very well in specific process medias. Offers the highest resistance to abrasion out of the materials listed. NR is a tough material with a high durometer and stiffness. | 212 |

| PTFE | Offers the best chemical resistance of all listed liners. Soft material subject to plastic deformation and cold flow. Very low resistance to abrasion. | 350 |

Ambient Temperature Limits

Determined by the Pressure Instrument

Download Installation Instructions: