What are diaphragm seals for?

Diaphragm seals are used to protect pressure instruments from corrosive, viscous, or abrasive process media. They isolate the instrument from the process fluid, extending its lifespan and ensuring accurate measurements in challenging conditions.

What is a diaphragm seal?

A diaphragm seal, also known as a chemical seal, is a device used to protect pressure instruments from harsh process conditions. It consists of a flexible diaphragm that separates the process fluid from the pressure sensor. This isolation prevents corrosive, abrasive, or viscous media from directly contacting the instrument, ensuring accurate measurements and prolonging the instrument’s lifespan. The pressure exerted on the diaphragm is transmitted hydraulically to the instrument through a fill fluid, maintaining accurate pressure readings while keeping the instrument safe from damage.

Does a diaphragm seal affect the instrument’s performance?

When correctly installed and filled, a diaphragm seal assembly minimally impacts the instrument’s performance.

What are the application considerations for diaphragm seals?

REOTEMP Diaphragm Seal Assemblies are carefully designed, built, and tested to maximize performance, increase instrument lifespan, and assure operator safety. The following should be considered when specifying a diaphragm seal:

Instrument Considerations

- Is there sufficient displacement to drive through its

full range? - Is the diaphragm sensitive enough for the measuring range and accuracy grade of the instrument?

Diaphragm Seal Selection – Picking the Right Diaphragm Material

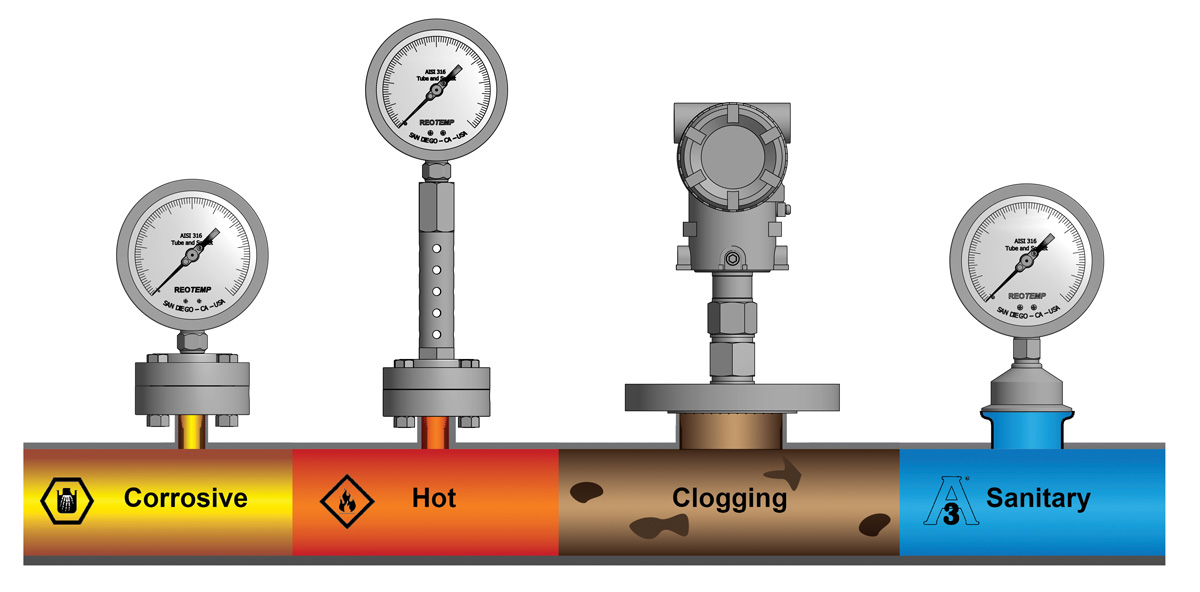

Diaphragm Seals, also known as Chemical Seals or Gauge Isolators, are built to protect pressure measurement instrumentation from process fluid that is hot, clogging, corrosive, sanitary, or otherwise threatening to the instrument. One of the most important aspects in selecting a long-lasting diaphragm seal is choosing the diaphragm foil material. Let Reotemp help you select a diaphragm material that will increase the durability and reliability of your pressure instrument.

Diaphragm Seal Sizing – Selecting the Right Size Diaphragm

Selecting the right size diaphragm is a crucial element in ensuring an accurate, durable, and cost effective pressure measurement assembly. Reotemp offers three standard sizes for offline diaphragm seals. Learn what applicational factors to look out for when selecting which size to use.

Diaphragm Seal Flushing Connections

Many styles of diaphragm seals allow for the installation of flushing connections, providing the user access to drain, purge, flush, or sample the process fluid inside of the diaphragm seal cavity. This video explains some of the flushing connection options available when configuring a diaphragm seal.

Benefits of All Welded Diaphragm Seals vs Bolted Diaphragm Seals

Diaphragm Seals, also known as Chemical Seals or Gauge Isolators, are used to isolate pressure instrumentation, like pressure gauges, pressure transmitters, pressure switches, level transmitters, and more from process media that is hot, corrosive, clogging, or otherwise damaging to the pressure instrument. In this video we compare Bolted Offline Diaphragm Seals with All Welded Diaphragm Seals, also known as Seal Gauges.

Diaphragm Seal Mounting

- How will the diaphragm seal mount to the process? Threaded? Flanged? Clamped?

- How will the instrument mount to the diaphragm seal? Threaded? Welded?

- Will the instrument be mounted directly to the seal or

with capillary?

Process Characteristics

- What are the pressure and temperature limits?

- Are there issues with clogging or high viscosity?

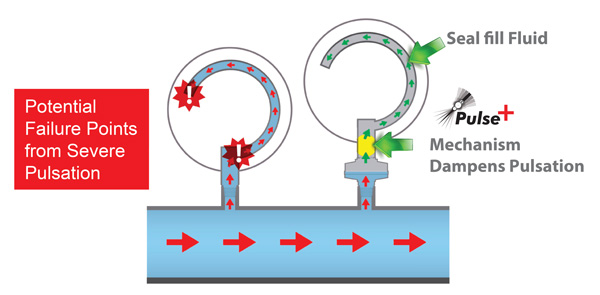

- Is there severe shock and pulsation?

- Is the process fluid compatible with the wetted material and gasket?

Diaphragm Seal Accuracy – How Temperature Impacts Pressure Reading

When a pressure transmitter or pressure gauge requires a diaphragm seal, properly selecting the size of the diaphragm is crucial. Undersized diaphragms can lead to many performance issues including sensitivity to temperature drift. This video illustrates how temperature change can impact the accuracy of a pressure instrument installed with a 3/4” Triclamp diaphragm seal – a common configuration for the sanitary market.

Ambient Characteristics

- Are there extreme or fluctuating ambient temperatures?

- Is the outside environment corrosive?

How to Avoid Diaphragm Seal Temperature Drift

A common issue with diaphragm seal performance is that of ambient temperature drift. Watch to learn one simple way to solve this problem.

Vacuum Considerations

- Will the assembly be operating in deep vacuum (< 5psia)? If yes, contact the factory with process specifications.

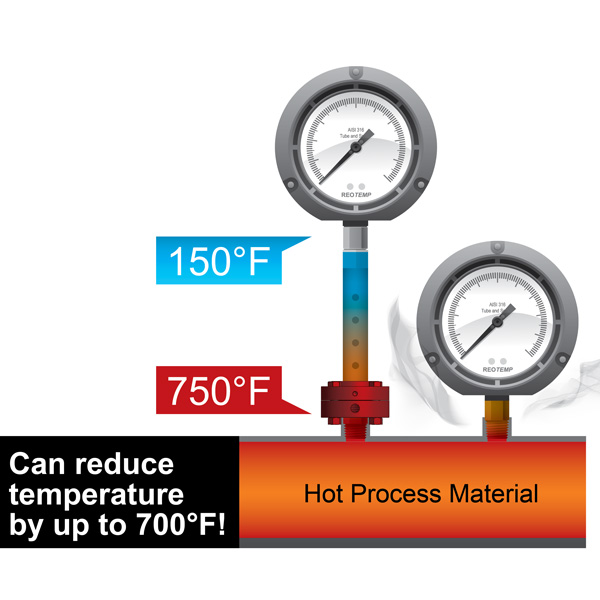

Cooling Towers

High process temperatures are damaging to pressure instrument performance and could pose an imminent safety risk. REOTEMP cooling towers provide the best option for extending instrument lifespan, improving performance and minimizing safety risk.

Pulsation Protection

Process media pulsation is one of the most common causes of pressure gauge failure. REOTEMP’s proprietary diaphragm seal feature, Pulse Plus™ dramatically reduces the effects of pulsation on mechanical pressure instruments. Specify with option code -PP on most diaphragm seal models when a seal is being mounted to a REOTEMP pressure gauge.

Process media pulsation is one of the most common causes of pressure gauge failure. REOTEMP’s proprietary diaphragm seal feature, Pulse Plus™ dramatically reduces the effects of pulsation on mechanical pressure instruments. Specify with option code -PP on most diaphragm seal models when a seal is being mounted to a REOTEMP pressure gauge.